◘ Pneumatic Conveying System

(KRTB-7555-V10)

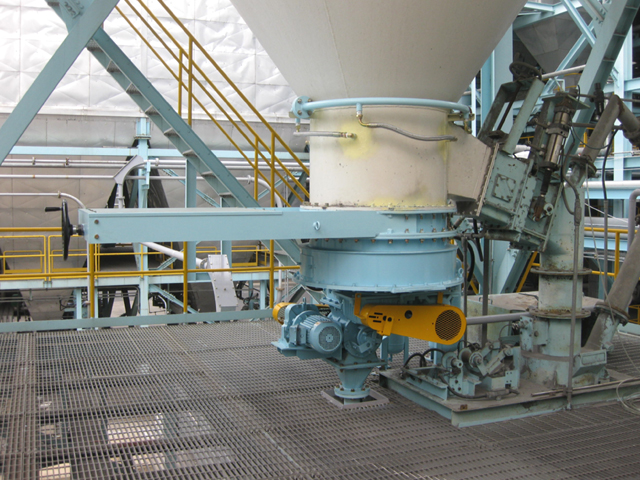

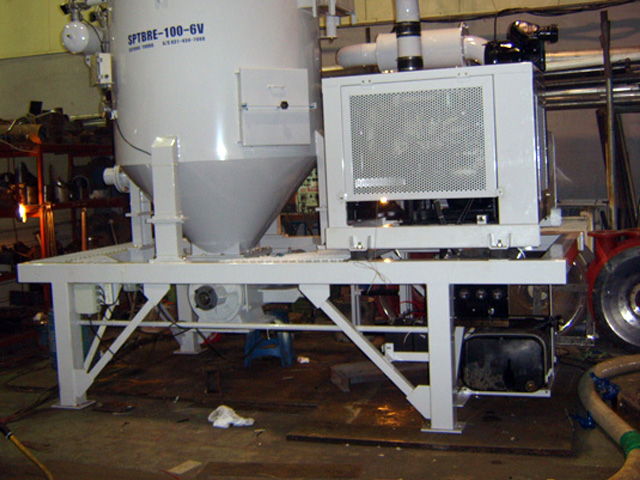

The pressure-transmitting transfer device can transfer 1 to 70 tons per hour up to a maximum distance of about 500 meters and a height of 100 meters. It can meet strengthened environmental safety standards by replacing the existing belt conveyor with a lot of dust.

| T Y P E | SEPARATING/Continuous Discharge Type AUTO DAMPER |

|---|---|

| Product Line Up | ~ 710 kW |

| Maximum discharge pressure | 400 CMM |

| Max Pressure | 10,000 mmAq |

| Transfer pipe diameter | Φ 50~500 |

| Vent Dust Collector | Cartridge or Bag Type |

◘ Dust Collection Unit Operating Instructions

1. Configuration

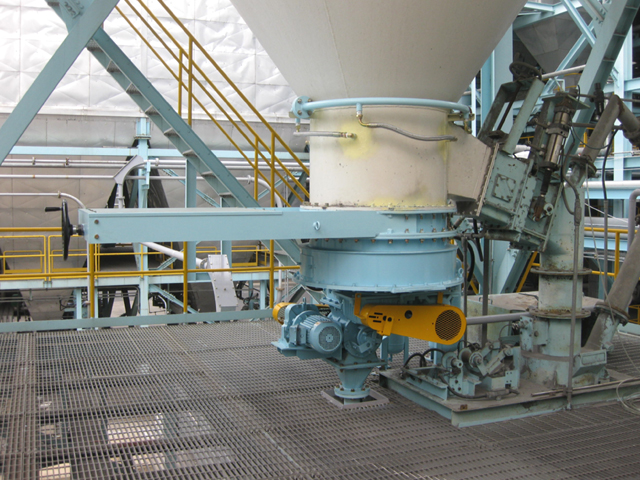

Suction-type and pressure-type pneumatic conveyors use blowers to transport particles, utilizing suction and discharge pressure, respectively.

In a pressure-type system, a vent dust collector is located at the top of the silo, while in a suction-type system, a dust collector is positioned to separate the air from the transported particles.

As the conveying capacity increases, the capacity of the vent and suction dust collectors also increases proportionally.

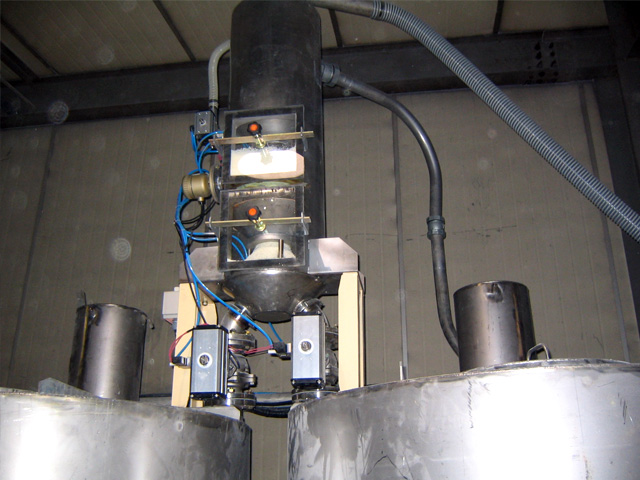

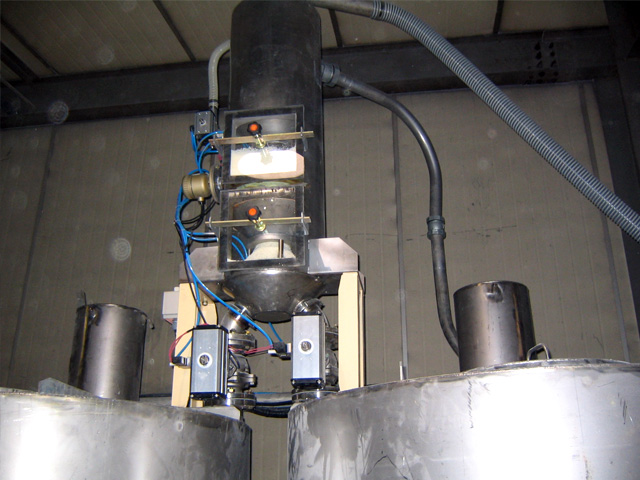

2. Discharge Device

The continuous discharge system at the bottom applies a rotary valve and double damper.

⦁ Example of use

↓ Click on the photo Big pictureYou can see .

-

Scale treatment unit in boiler tube

-Sunboiler, Mars Boiler, etc -

for transporting wet rice

Daepyeong Food -

for feed transfer

Korean media -

For the transfer of lab rat's straw

Orient Bio -

For transferring resin raw materials

Korea and Japan, too -

For cleaning aluminum

processing chips -

For short ball transfer

Shot Boll Vacuum Recovery Shstem

Seongsan Bridge -

for sand recovery

Gwangyang Steelworks -

For heating furnace scale cleaning

Gwangyang Steelworks -

For scale-scaling,

multi-purpose transfer ... -

For transferring activated

carbon (engine type) ... -

Grinder Chip Removal

Gwangyang Steelworks -

Salt cabbage waste

pulverization and transfer y -

Aluminum chip recovery

Mando Pyeongtaek plant -

Short ball recovery

Namkwang Engineering... -

Slaked lime, Limestone

Feeding System Removal, ... -

Slaked lime, Limestone

Feeding System Removal, ... -

In the case of insulation

-for transfer of Styrofoam ... -

In the case of insulation

-for transfer of Styrofoam ... -

For boiler short

... -

cement transfer industry

... -

Central University for the

transportation of huts -

Coffee sludge transfer device,

jadeng -

Transfer Device

Powder (for vacuum/pressure) -

For scale transfer

Pohang Steelworks -

Short ball recovery machine

... -

Sawdust transfer

Korea Media -

Limestone Transfer

Philippines Power Station -

ASH Transfer

Military Energy -

For sending activated carbon

SA carbon -

For dust cleaning/absorption/discharging ...

-

For dust cleaning/absorption/discharging ...